Home > Steel Standards

Home > Steel Standards

High temperature alloy seamless steel tubes pipes X11CrMo9-1+NT

Relative steel grades:15NiCuMoNb5-6-4,7CrWVMoNb9-6,7CrMoVTiB10-10,X11CrMo5+I,

X11CrMo5+NT1,X11CrMo5+NT2,X11CrMo9-1+I,X11CrMo9-1+NT,X10CrMoVNb9-1,X10CrWMoVNb9-2,X11CrMoWVNb9-1-1,X20CrMoV11-1

Main application:Non-alloy and alloy high temperature seamless steel pipes more used for building boilers and pressure vessels’parts.X11CrMo9-1+NT alloy seamless steel pipes have to be done Normalized plus Tempered heat treatment.

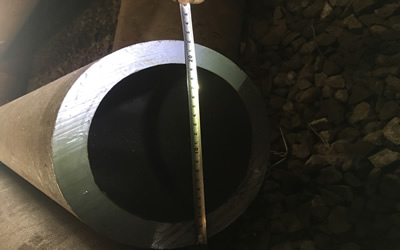

Rolling range:A) Diameter:1/2’’ to 36’’ B) Schedule:SCH20-SCHXXS C) O.D.:13.7MM-914.4MM D) Wall Thickness: 2.11MM-60MM E) Length: Max.17MM

Test: Low temperature impacting test,Ultrasonic examination,Heat treatment,Bending test,Eddy test,Hydrostatic test,High tension test.

Want to get more information about Abrasion resistant steel plate,please CONTACT XINSTEEL NOW

►Mechnical property for X11CrMo9-1+NT pressure vessel steel pipes:

|

Yield strength (≥Mpa) |

Tensile strength (≥Mpa) |

Elongation A min. % | ||||

|

T≤16 |

16<T≤40 |

40<T≤60 |

60<T≤100 |

|

Longitudinal |

Transverse |

|

390 |

390 |

390 |

- |

590-740 |

18 |

16 |

►Chemical composition for X11CrMo9-1+NT steel tubes (Cast Analysis Max%)

|

Main chemical elements composition of X11CrMo9-1+NT | |||||||

|

C |

Si |

Mn |

P |

S |

Cr |

V | |

|

0.08-0.15 |

0.25- 1.00 |

0.30-0.60 |

0.025 |

0.010 |

8.0-10.0 |

- | |

|

Mo |

Ni |

Al total |

Cu |

Nb |

Ti |

B | |

|

0.90-1.10 |

- |

0.040 |

0.30 |

- |

- |

- | |