Home > Steel Standards

Home > Steel Standards

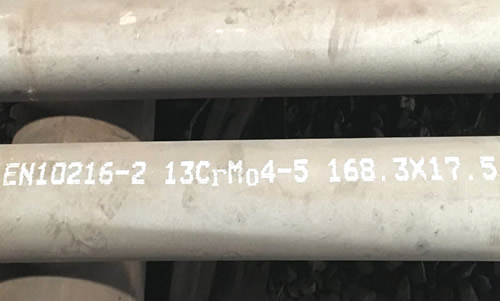

Cr-Mo alloy Seamless Pipe 10CrMo9-10 and Seamless tube 13CrMo4-5 both supplies from european specification EN 10216-2.Seamless Pipe 10CrMo9-10 shall be heat treatment with Normalising and Tempering,Austenitizing temperature with 900-960 ℃,tempering temperature at 660-730 ℃.Cooling medium after heat treament in Air.Seamless tube 13CrMo4-5 shall be heat treatment with Normalising and Tempering,Austenitizing temperature with 900-960 ℃,tempering temperature at 660-750 ℃.Quenching and Tempering heat treatment also can be done for Seamless Pipe 10CrMo9-10 and Seamless tube 13CrMo4-5 if customer demands.

In specification EN 10216-2,there are other relative alloy seamless steel pipes 16Mo3 seamless pipe,13crmo4-5 seamless tube,10crmo9-10 seamless steel pipe,25crmo4 seamless steel pipe,15NiCuMoNb5-6-4 seamless steel pipe,X10CrMoVNb9-1 seamless pipe and X20CrMoV11-1 seamless pipe,15NiCuMoNb5-6-4 seamless pipe.

Comparasion with EN 10216-2 Seamless Pipe 10CrMo9-10 and Seamless tube 13CrMo4-5:

|

10CrMo9-10 13CrMo4-5 |

Chemical composition: Heat Analysis Max% | ||||||||||

|

Standard |

Grade |

C |

Mn |

P |

S |

Si |

Cu |

Cr |

Ni |

Mo |

Alt tot |

|

EN 10216-2 |

10CrMo9-10 |

0.08-0.14 |

0.3-0.7 |

0.025 |

0.020 |

0.50 |

0.30 |

2.0-2.5 |

0.30 |

0.9-1.1 |

0.04 |

|

EN 10216-2 |

13CrMo4-5 |

0.10-0.17 |

0.4-0.7 |

0.025 |

0.020 |

0.35 |

0.30 |

0.7-1.15 |

0.30 |

0.4-0.6 |

0.04 |

|

Mechanical Properties: |

Thickness |

Yield strength |

Tensile strength | ||||||||

|

Mpa Min. |

Mpa | ||||||||||

|

EN 10216-2 |

10CrMo9-10 |

T≤16 |

280 |

480-630 | |||||||

|

EN 10216-2 |

13CrMo4-5 |

T≤16 |

290 |

440-590 | |||||||